Page 2 of 3

Re: How to Make a Steam Box/Cabinet

Posted: Wed Oct 30, 2013 11:49 am

by heartwood

reported

Re: How to Make a Steam Box/Cabinet

Posted: Tue Jan 28, 2014 11:22 pm

by Carmify (WavyGlass)

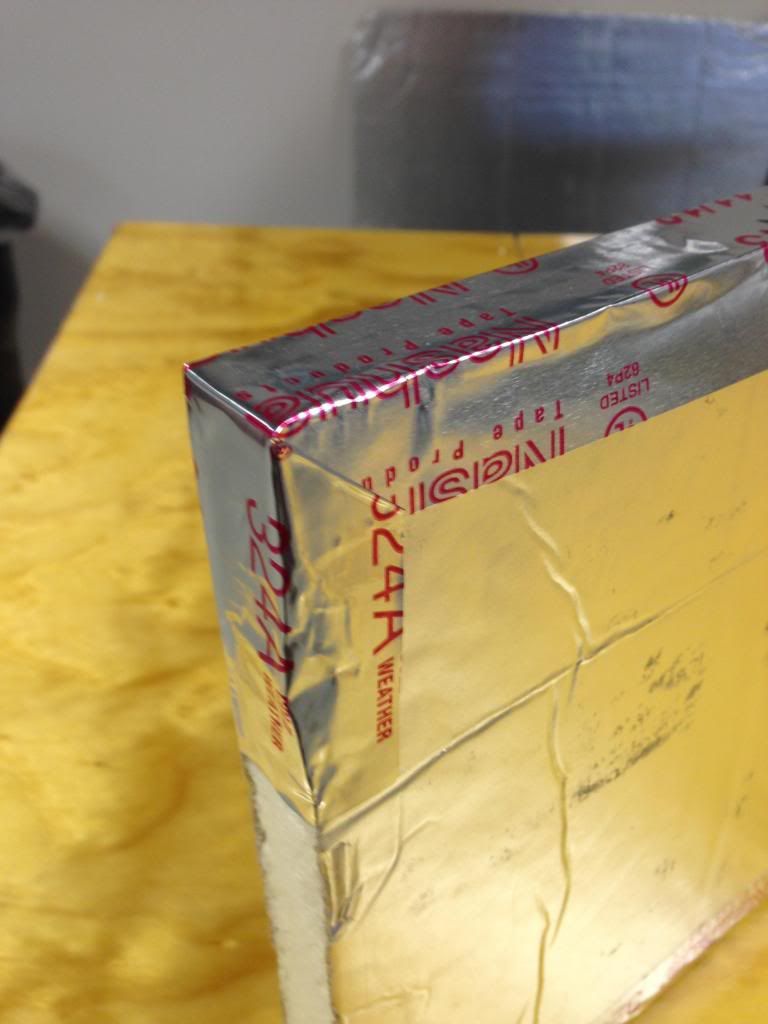

We made this steam box over the weekend, following this thread's directions. We made it 4x4. It took two 8x4 pcs foam-board, 2 tubes of caulk, four 8-ft lengths of strapping and 1 roll of foil tape. Other things we had on hand, like nail gun and wood glue, came in handy.

Christmas-present corner. All the taping is very tedious.

Creative taping for steamer-nozzle hole!

Re: How to Make a Steam Box/Cabinet

Posted: Wed Jan 29, 2014 1:02 am

by heartwood

woohoo, look great!! yup, lots of taping...wait til you use the steamer...depending on how hard the putty is, it could take 45 minutes to a couple of hours...you only have about 10-15 minutes to work on the putty before it begins to get hard again...if you have 6 over 6 sash, i suggest completely removing three then put the sash back in and begin another...

i look forward to your progress report! good luck!

....jade

Re: How to Make a Steam Box/Cabinet

Posted: Wed Jan 29, 2014 1:00 pm

by Carmify (WavyGlass)

Thanks Jade! I am dying to use it, but I've read that there can be an issue with glass-breakage due to the temperature extremes and that (as always) there's a learning curve. I think it might be kinder to my glass to start when the temp in my workshop is not in the teens. I seriously don't know if I'm going to be able to wait....

Re: How to Make a Steam Box/Cabinet

Posted: Wed Jan 29, 2014 6:28 pm

by heartwood

indeed, glass breakage can be the result of putting a very cold sash into a heated box...our shop is about 55-65 degrees...we put sash in the box then let the steam build up...when you open the door to remove or install another, the temp in the box comes way down for a short period of time...overall, removing glass and putty with a steam box vastly reduces glass breakage...

ya, a shop in the teens would not be good for sash nor person!

Re: How to Make a Steam Box/Cabinet

Posted: Mon Jul 07, 2014 7:09 pm

by opmal7 (WavyGlass)

When you steam the windows, do you fill the box with steam and shut the steamer off? Or do you run the steamer the whole time?

Re: How to Make a Steam Box/Cabinet

Posted: Mon Jul 07, 2014 7:54 pm

by heartwood

refill the water in the steamer and run the steamer continuously...we typically shut the steamer off when the last sash is 'cooked'...depending on sash size, glazing putty volume and hardness of the putty, a sash may remain in the steamer for 45 minutes up to 3 hours...our steambox can hold a minimum of 3 sash...the putty remains soft for about 10-15 minutes at which time the putty can be completely removed or the sash put back in the steamer for longer rotating the sash as is called for...

stay in touch with this community if you are ready to undertake window restoration...we like to support and praise!

...jade

Re: How to Make a Steam Box/Cabinet

Posted: Mon Jul 07, 2014 8:03 pm

by opmal7 (WavyGlass)

Thanks for the info. I have a little handheld steamer, but I doubt it will be big enough so I'm looking for a new (or used) one.

I have 17 windows that I'll be restoring. First step is building the steam box. I bought all the hardware and cut the pieces this weekend. I'll be piecing it together this week. Maybe I'll post some pictures when I'm done.

Re: How to Make a Steam Box/Cabinet

Posted: Mon Jul 07, 2014 10:26 pm

by heartwood

oh yes indeed, you MUST post pictures!!! we love that here, almost a prerequisite....

may i suggest you introduce yourself on the 'introductions' thread?

good luck putting the box together...

...jade

Re: How to Make a Steam Box/Cabinet

Posted: Wed Jul 09, 2014 12:08 pm

by historicalwork

opmal7 - you probably already knew this, but it seems like a lot of people go for the Jiffy Steamers. I don't know if there are other brands to look for. My wife had a smaller Jiffy steamer for wedding gowns but I decided to find one on ebay for the steam box I made (like yours). It was an old one but seemed to work fine for this purpose. I think I pad around $70 because some parts were missing - but it didn't impact what I needed. The one I have seems to take forever to reach temp and the steam dies down quickly so leaving it on for the time the window is in there seems to make sense. Interestingly, I was trying to get smart by putting a piece of PVC inside the steam box - sort of a manifold that would "distribute" the stream. The steam softened that pipe so quickly and it folded down like a pretzel. It's quick reminder how quickly steam can burn. I don't even know if it would make any difference. But, if I had more windows to do, I was going to waste more time using metal tubing or something create something inside the box to evenly apply the steam. I think it was more about making something than really needing to do it!

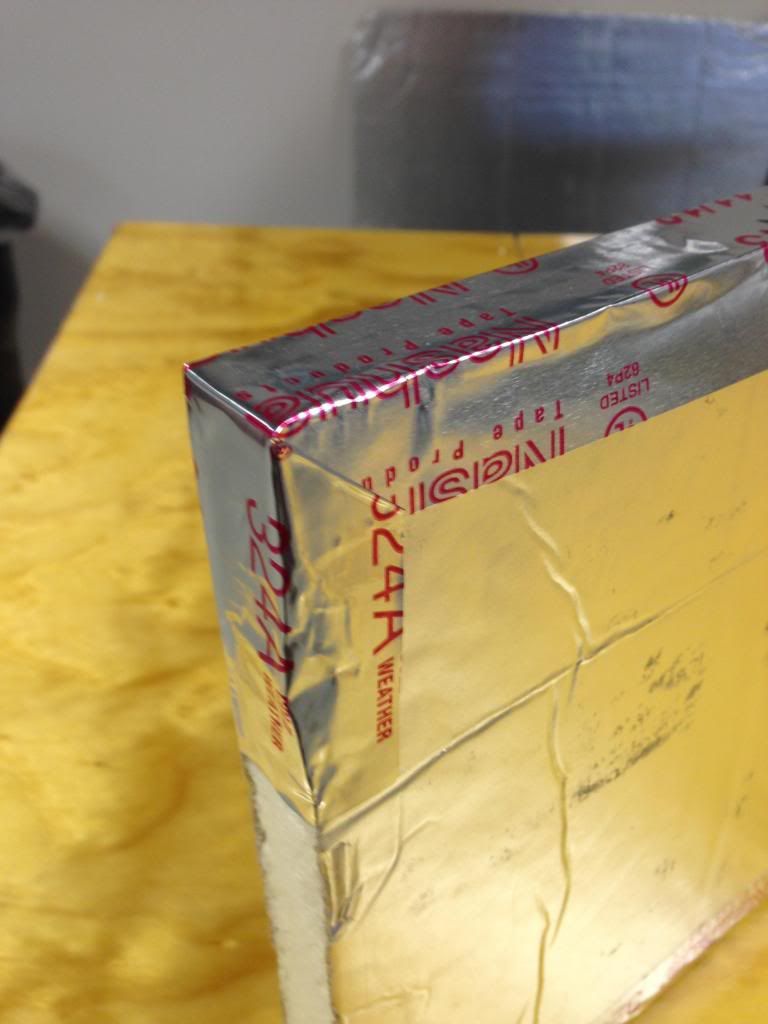

I've posted before, but I'll post my steambox again for reference - same as others for the most part... I should add that I had it upright when using - steam coming in at the top and any condensation coming out the bottom (I tilted it a little).

[img=center]https://lh6.googleusercontent.com/-3j6_GN3pW8A/UhgvyrlMkvI/AAAAAAAAAR4/fiDyi_sx1n4/w892-h669-no/Steambox01.JPG[/img]