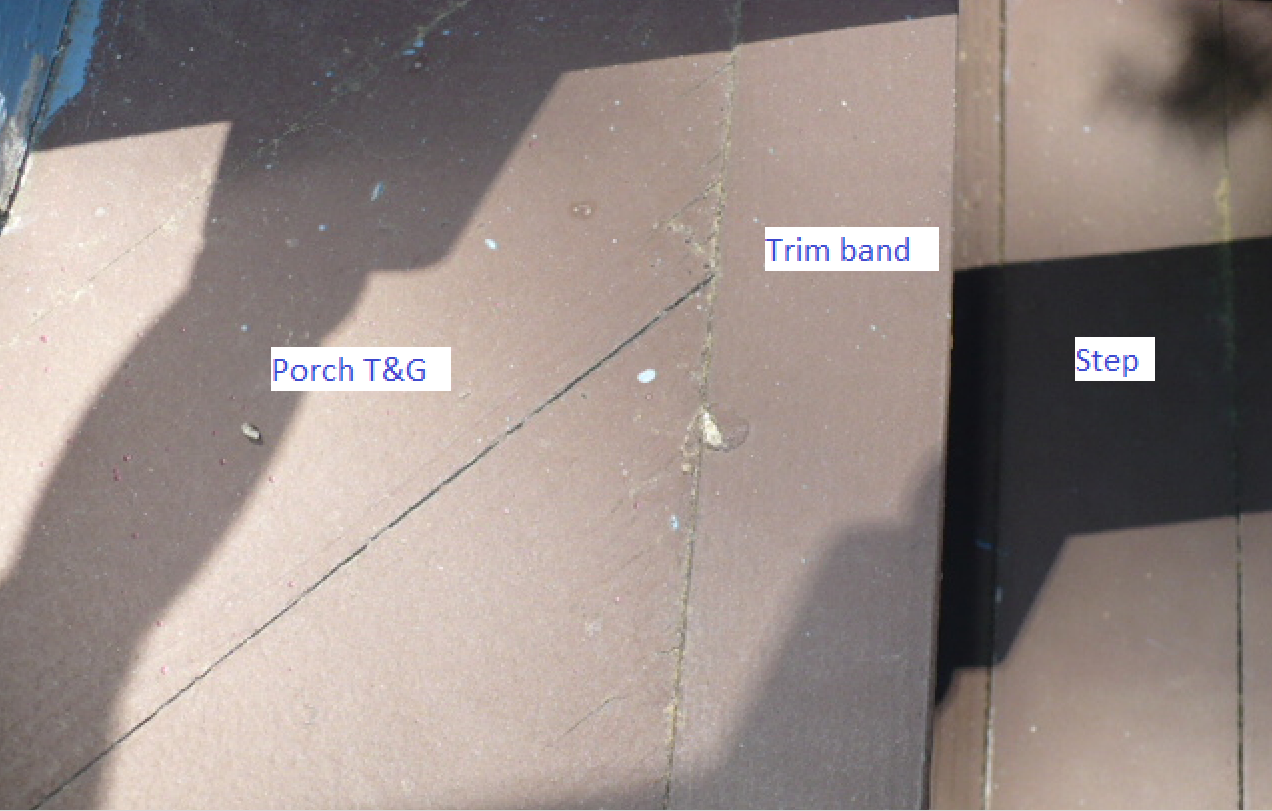

Olson185 wrote: I've been noticing that mitered perimeter trim, along the edge of porches and steps, is rarely used any more. Wicking is inhibited and repair is easier if one is dealing with a piece of trim rather than the full-length boards. Porch Trim Band

Olson you are right - I don't see porches trimmed that way anymore but I remember them. I LOVE this idea because, as you mention, it is the outside ends that suffer the most from rot problems.

If only I could figure out how to apply this method on the round corner of the wrap around porch. Hmm... Is it possible?